The 1997 Jeep Wrangler TJ, a beloved icon of off-roading prowess, is renowned for its ruggedness and simplicity. At the heart of this legendary vehicle lies its frame, the steel backbone that provides structural integrity and supports all other components. Understanding the frame and its constituent parts is crucial for maintenance, repair, restoration, and even customization. This comprehensive guide will delve into the world of 1997 Jeep Wrangler (TJ) frame parts, covering everything from identification and common issues to repair techniques and aftermarket options.

Introduction: The Foundation of Adventure

1997 Jeep Wrangler (TJ) Frame Parts: A Comprehensive Guide

The frame of a 1997 Jeep Wrangler TJ isn't just a collection of metal; it's the foundation upon which the entire vehicle is built. It's a ladder-style frame, meaning it consists of two parallel rails connected by crossmembers. This design provides a robust platform for handling the stresses of off-road driving, towing, and everyday use. However, even the toughest frames are susceptible to wear and tear, especially in regions with harsh climates or frequent off-road excursions. Recognizing the importance of each frame component and understanding potential problems allows owners to maintain their TJ's structural integrity and ensure years of reliable performance.

I. Understanding the 1997 TJ Frame Components

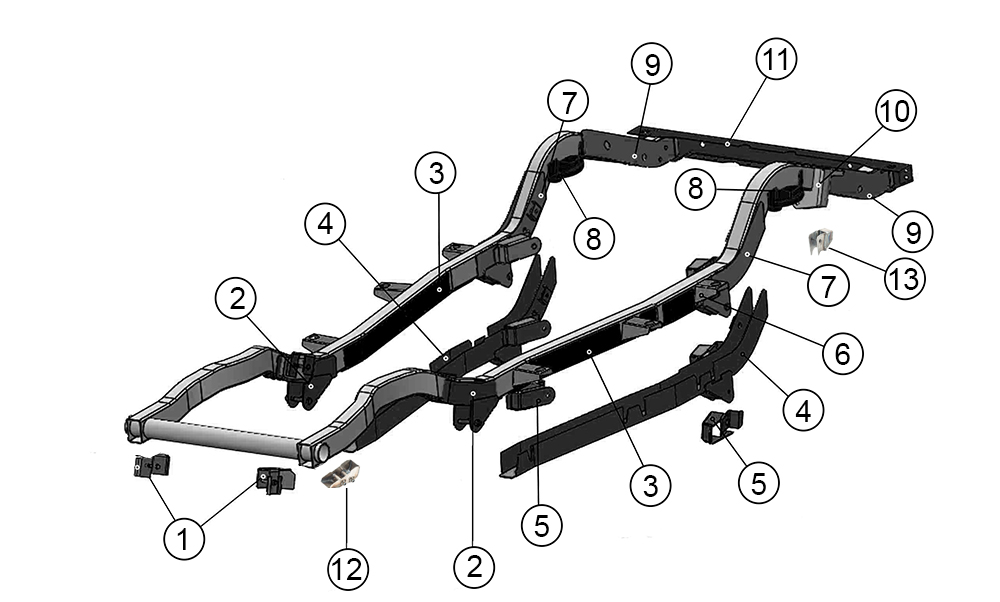

The 1997 TJ frame is comprised of several key parts, each playing a vital role in its overall strength and function:

- Frame Rails: The primary load-bearing elements of the frame. These long, parallel steel beams run the length of the vehicle and provide the foundation for mounting other components. They are typically made from boxed or C-channel steel for maximum strength.

- Crossmembers: These connect the two frame rails, providing lateral stability and preventing the frame from twisting or flexing excessively. Different types of crossmembers exist, each serving a specific purpose. Common examples include:

- Transmission Crossmember: Supports the transmission and transfer case.

- Skid Plate Crossmember: Often integrated with the transmission crossmember, it protects the drivetrain components from impacts.

- Rear Crossmember: Located at the rear of the frame, it provides mounting points for the bumper, trailer hitch (if equipped), and other rear-end components.

- Body Mounts: These rubber or polyurethane bushings isolate the body from the frame, reducing vibration and noise. They are strategically placed along the frame rails to support the body tub.

- Spring Perches/Mounts: These welded-on brackets provide attachment points for the coil springs, which are a defining feature of the TJ's suspension.

- Control Arm Mounts: These brackets secure the control arms, which control the axle's movement and articulation.

- Steering Box Mount: A reinforced section of the frame specifically designed to mount the steering box, ensuring precise and responsive steering.

- Bump Stop Mounts: These small brackets provide a landing point for the bump stops, preventing the suspension from over-compressing.

- Track Bar Mounts: Secure the track bar, which keeps the axle centered under the vehicle.

II. Common Issues with 1997 TJ Frames

Despite their robust design, 1997 TJ frames are prone to certain issues, especially in older vehicles:

- Rust: The most common enemy of any steel frame, rust is particularly prevalent in areas with road salt or high humidity. Rust typically starts in areas where moisture and debris accumulate, such as inside boxed sections, around body mounts, and along weld seams.

- Cracking: Stress and fatigue can lead to cracks in the frame, particularly around welds, suspension mounts, and the steering box mount. Cracking can weaken the frame and compromise its structural integrity.

- Bent Frames: Severe impacts or accidents can bend or warp the frame, affecting the vehicle's alignment and handling.

- Damaged Body Mounts: Deteriorated or damaged body mounts can cause excessive vibration, noise, and even body damage.

- Stripped Threads: Over-tightening bolts or corrosion can strip the threads in frame-mounted components, making it difficult to secure them properly.

III. Inspection and Diagnosis

Regular inspection is key to identifying potential frame issues before they become major problems. Here's what to look for:

- Visual Inspection: Thoroughly inspect the entire frame for signs of rust, cracks, bends, or damage. Pay close attention to the areas mentioned above.

- Rust Assessment: Use a hammer or screwdriver to gently tap suspect areas. If the metal sounds hollow or crumbles easily, it's likely heavily rusted.

- Body Mount Check: Inspect the body mounts for cracks, deterioration, or separation. Bounce the body to check for excessive movement or noise.

- Suspension Mount Inspection: Check the spring perches, control arm mounts, and track bar mounts for cracks, damage, or loose bolts.

- Steering Box Mount Inspection: Look for cracks around the steering box mount, especially where it's welded to the frame. Have someone turn the steering wheel while you observe the mount for movement or flex.

- Alignment Check: If you suspect a bent frame, have the vehicle's alignment checked by a professional.

IV. Repairing a 1997 TJ Frame

The extent of the repair will depend on the severity of the damage. Minor surface rust can often be treated with rust converters and protective coatings. More serious rust or cracking may require welding repairs or even frame replacement.

- Rust Repair:

- Surface Rust: Wire brush or sandblast the affected area to remove loose rust. Apply a rust converter to neutralize the remaining rust and then prime and paint the area.

- Significant Rust: Cut out the rusted section and weld in a new patch panel. Ensure the patch panel is properly fitted and welded to maintain the frame's structural integrity.

- Crack Repair:

- Small Cracks: Grind out the crack and weld it shut. Reinforce the area with a reinforcing plate if necessary.

- Large Cracks: The area needs to be inspected by a professional welder. Grinding out the crack and weld it shut. Reinforce the area with a reinforcing plate if necessary.

- Body Mount Replacement:

- Remove the old body mounts and clean the mounting surfaces. Install new body mounts, ensuring they are properly aligned and torqued.

- Frame Replacement:

- In cases of severe damage or extensive rust, frame replacement may be the only viable option. This is a complex and time-consuming process that typically involves removing the entire body and transferring all components to the new frame.

Important Considerations for Frame Repair:

- Welding Expertise: Frame welding should only be performed by a qualified and experienced welder. Improper welding can weaken the frame and compromise its safety.

- Safety Precautions: Wear appropriate safety gear, including eye protection, gloves, and a respirator, when working with rust, welding, or grinding.

- Proper Materials: Use high-quality steel and welding rods that are compatible with the frame material.

- Thorough Inspection: After completing any frame repair, thoroughly inspect the work to ensure it's structurally sound and meets safety standards.

V. Aftermarket Frame Options and Upgrades

For those seeking to replace or upgrade their 1997 TJ frame, several aftermarket options are available:

- Direct Replacement Frames: These frames are designed to be a direct bolt-in replacement for the original frame. They are typically made from heavier-gauge steel and may include additional features, such as reinforced mounts or integrated skid plates.

- Modified Frames: These frames offer a range of modifications, such as longer wheelbases, different suspension configurations, or custom mounting points. They are often used for specialized builds or extreme off-road applications.

- Frame Reinforcement Kits: These kits include components that can be welded onto the existing frame to reinforce weak areas, such as the steering box mount or suspension mounts.

VI. Tips for Maintaining Your 1997 TJ Frame

- Regular Cleaning: Regularly wash the undercarriage of your TJ, especially after off-road excursions or exposure to road salt.

- Rust Prevention: Apply rust inhibitors or undercoating to protect the frame from corrosion.

- Touch-Up Paint: Repair any scratches or chips in the frame's paint to prevent rust from forming.

- Proper Lubrication: Lubricate body mounts and suspension components to prevent wear and noise.

- Periodic Inspection: Conduct regular visual inspections of the frame to identify potential problems early on.

VII. Potential Challenges and Solutions

- Difficulty Accessing Certain Areas: Some areas of the frame can be difficult to access for inspection or repair. Using mirrors, flexible inspection cameras, or removing components can help.

- Frozen or Corroded Bolts: Corroded bolts can be difficult to remove. Use penetrating oil, heat, or bolt extractors to loosen them.

- Finding Qualified Welders: Not all welders are experienced in frame repair. Seek out welders who specialize in automotive or off-road fabrication.

- Cost of Frame Replacement: Frame replacement can be an expensive undertaking. Consider all options carefully and weigh the cost against the value of the vehicle.

VIII. 1997 Jeep Wrangler Frame Parts - Price Guide

| Part | Description | Estimated Price Range | Notes |

|---|---|---|---|

| Bare Frame (New) | Complete replacement frame | $2,500 - $4,500+ | Prices vary widely based on manufacturer, coating (e.g., powder coating), and any included reinforcements. Installation not included. |

| Used Frame | Pulled from a salvage vehicle | $800 - $2,000 | Price depends on condition, rust level, and availability. Requires careful inspection for damage. May need significant repair. |

| Frame Repair Sections | Pre-made steel sections for rust repair | $50 - $200 per section | Designed to be welded into the existing frame. Available for common rust areas. Requires skilled welding. |

| Body Mounts (Set) | Complete set of body mount bushings | $50 - $150 | Price varies based on material (rubber vs. polyurethane) and brand. Polyurethane mounts offer increased durability but can transmit more vibration. |

| Transmission Crossmember | Supports transmission and transfer case | $150 - $400 | Aftermarket crossmembers may offer increased strength or clearance. |

| Spring Perches | Mounts for coil springs | $20 - $50 per perch | Typically sold as a pair. Welding required. |

| Control Arm Mounts | Mounts for control arms | $30 - $75 per mount | Welding required. |

| Steering Box Mount Reinforcement | Reinforcement plate for steering box area | $50 - $150 | Helps prevent cracking in this high-stress area. Welding required. |

| Bump Stops | Prevents excessive suspension travel | $20 - $50 per pair | Available in various lengths and materials. |

| Rust Converter | Chemical treatment to neutralize rust | $15 - $40 per can | Converts rust into a stable substance that can be painted over. |

| Undercoating | Protective coating to prevent rust | $20 - $50 per can | Applied to the frame to protect it from moisture and corrosion. |

| Penetrating Oil | Used to loosen rusted bolts | $10 - $25 per can | Essential for working on older vehicles. |

| Welding Services (Frame Repair) | Professional welding for frame repairs | $75 - $150+ per hour | Price varies based on the complexity of the repair and the welder's experience. Obtain multiple quotes. |

Disclaimer: Prices are estimates and may vary depending on location, vendor, and specific product. Always research and compare prices before making a purchase.

IX. Frequently Asked Questions (FAQ)

- Q: How can I tell if my TJ frame is rusted beyond repair?

- A: Extensive rust that has weakened the frame significantly, large holes, or multiple cracks in critical areas may indicate that the frame is beyond repair. A professional inspection is recommended.

- Q: Can I weld my TJ frame myself?

- A: While it's possible to weld your frame yourself, it's strongly recommended that you have experience and the proper equipment. Improper welding can compromise the frame's structural integrity and safety.

- Q: How often should I inspect my TJ frame?

- A: Inspect your frame at least twice a year, especially before and after the winter months or after any off-road excursions.

- Q: What's the best way to prevent rust on my TJ frame?

- A: Regular cleaning, rust inhibitors, and undercoating are the best ways to prevent rust. Avoid driving through standing water or mud whenever possible.

- Q: Are aftermarket frames worth the investment?

- A: Aftermarket frames can be a worthwhile investment if your original frame is severely damaged or if you're planning a significant build or customization.

- Q: Can I use POR-15 on my Jeep frame?

- A: Yes, POR-15 is a popular and effective rust-preventative coating for Jeep frames. Proper surface preparation is crucial for optimal results.

Conclusion: Preserving a Legacy

The 1997 Jeep Wrangler TJ frame is a critical component that deserves attention and care. By understanding its construction, common issues, and repair options, you can ensure that your TJ remains a reliable and capable off-road machine for years to come. Regular maintenance, prompt repairs, and, if necessary, thoughtful upgrades will preserve the legacy of this iconic vehicle and allow you to continue exploring the trails with confidence.

0 comments